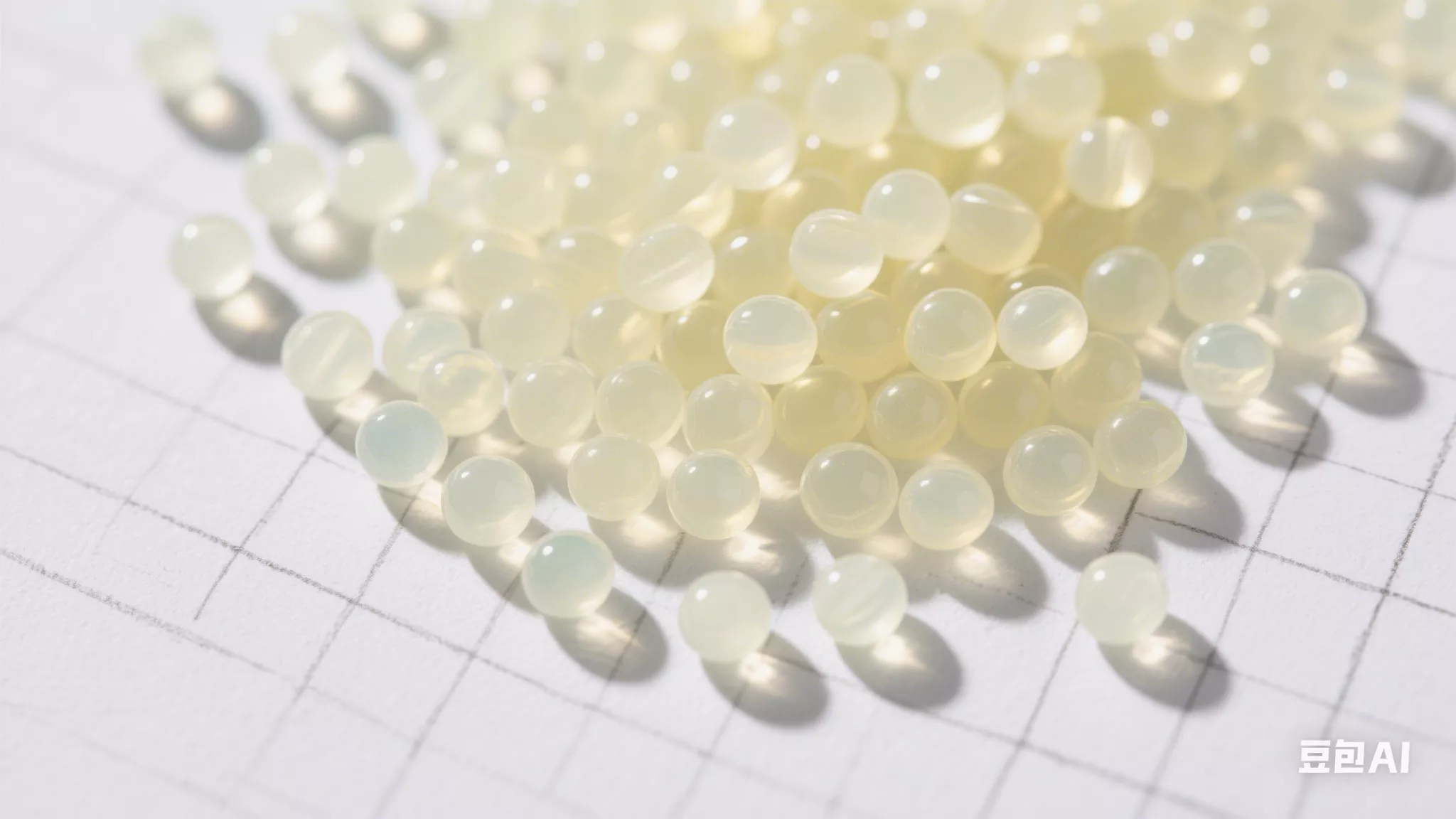

Reinforcing filler for tires and rubber products. Enhances abrasion resistance, tensile strength, and durability. Improves heat dissipation and UV stability. Widely used in automotive and industrial rubber components for extended service life.

rubber carbon black (rcb)

Product characteristics

2. Our in-house Pigment Application Laboratory in Malaysia allows for efficient formulation development and simulation, providing optimal performance and swift technical support.

3. We offer a wide range of high-performance products from leading manufacturers, ensuring reliability and quality.

4. With strong supply chain capabilities, AURETEK ensures timely delivery and consistent availability of products.

-

Description

-

Specification

-

Logistics & Stock

-

FAQ

-

Rubber Carbon Black (RCB) is a vital performance-enhancing material widely used in the rubber industry, playing a crucial role in the manufacturing of tires, hoses, belts, and various rubber products. It significantly improves the mechanical properties of rubber compounds by enhancing tensile strength, abrasion resistance, and tear resistance, thereby extending the service life of rubber products. RCB provides excellent reinforcement and helps rubber maintain its elasticity and flexibility under varying temperatures and environmental conditions. It also offers superior resistance to weathering and ozone attack, preventing cracks and degradation in rubber materials exposed to outdoor conditions. With good processing characteristics, RCB ensures easy mixing and dispersion in rubber compounds, facilitating manufacturing efficiency. Furthermore, it is a cost-effective solution that enhances the overall performance and durability of rubber products, making it an essential component in the production of high-quality rubber goods.

-

Product Standards Specificationand model N220 N330 N550 N660 N772 NSA m2/g 114±5 78±5 43±3 36±3 36±3 lodine Absorption g/kg 120±5 82±5 43±5 36±5 30±5 DBP Absorption cm3/100g 113±5 103±5 121±5 90±5 65±5 Ash contents max% <0.5 <0.5 0.45 0.45 0.48 Moisture max% 0.9 0.9 1 1 0.35 Residues on 45 μ max% 0.1 0.1 0.1 0.1 0.08 Toluene Discoloration max% <1.5 <1.5 1.1 1.1 80 Pour Density kg/m3 355±30 380±30 330 390 420 -

-

-

Q

What are the main benefits of using Rubber Carbon Black (RCB) in rubber products?

ARubber Carbon Black (RCB) offers several key benefits in rubber products. It significantly enhances the mechanical properties of rubber compounds by improving tensile strength, abrasion resistance, and tear resistance, which extends the service life of rubber products. RCB provides excellent reinforcement while helping rubber maintain its elasticity and flexibility under varying temperatures and environmental conditions. It also offers superior resistance to weathering and ozone attack, preventing cracks and degradation in rubber materials exposed to outdoor conditions. Additionally, RCB ensures easy processing with good mixing and dispersion properties, making manufacturing more efficient. These characteristics make RCB an essential component for producing high-quality rubber goods such as tires, hoses, and belts. -

Q

How does Rubber Carbon Black (RCB) enhance the durability of rubber products?

ARubber Carbon Black (RCB) enhances the durability of rubber products through its ability to improve key mechanical properties. By increasing tensile strength, it makes rubber products stronger and more resistant to breaking under stress. Its superior abrasion resistance reduces wear and tear during use, extending the product's lifespan. RCB also provides excellent resistance to weathering and ozone attack, which is crucial for products exposed to outdoor elements, as it prevents cracking and degradation. Furthermore, its ability to maintain elasticity and flexibility across different temperatures ensures that rubber products perform consistently in various environmental conditions. These properties collectively contribute to the enhanced durability and performance of rubber products. -

Q

How does Rubber Carbon Black (RCB) affect the processing of rubber compounds?

ARubber Carbon Black (RCB) facilitates the processing of rubber compounds by providing excellent mixing and dispersion properties. During the manufacturing process, RCB ensures that the rubber compound is uniformly mixed, which is crucial for achieving consistent product quality. Its fine particle size and high surface area allow for better distribution within the rubber matrix, enhancing the overall performance of the final product. Additionally, RCB's processing characteristics help in reducing the energy required for mixing and extrusion, making the production process more efficient and cost-effective. This ease of processing ensures that manufacturers can achieve high-quality rubber products with minimal production challenges.

-