Flexible, recyclable material combining rubber elasticity with thermoplastic processability. Resists temperature extremes, chemicals, and fatigue. Used in seals, grips, and soft-touch components. Reduces production costs and waste.

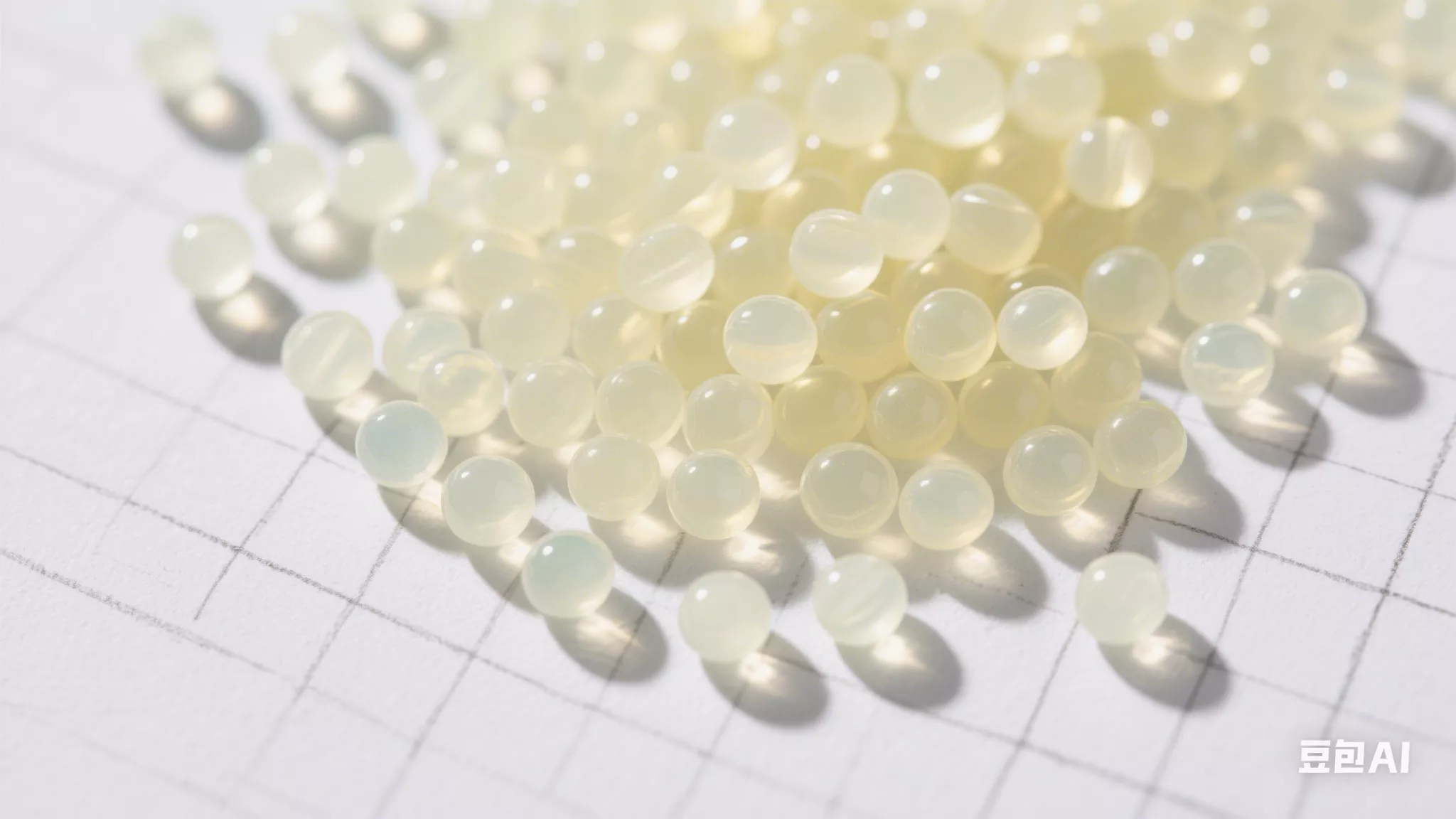

thermoplastic elastomer (tpe)

Product characteristics

2. Our in-house Pigment Application Laboratory in Malaysia allows for efficient formulation development and simulation, providing optimal performance and swift technical support.

3. We offer a wide range of high-performance products from leading manufacturers, ensuring reliability and quality.

4. With strong supply chain capabilities, AURETEK ensures timely delivery and consistent availability of products.

-

Description

-

Specification

-

Logistics & Stock

-

FAQ

-

Thermoplastic Elastomer (TPE) is a high-performance material that combines the flexibility of rubber with the processability of plastic, making it highly versatile across various industries. It offers excellent flexibility and elasticity, allowing it to return to its original shape after repeated deformation, which is crucial for applications requiring constant movement or flexibility. TPE also provides good abrasion resistance and durability, ensuring long-term performance even under harsh conditions. Its wide temperature resistance range makes it suitable for use in extreme environments, from very cold to very hot conditions. Additionally, TPE is easy to process and can be molded into complex shapes, offering manufacturers significant design freedom and reducing production costs. Being environmentally friendly, TPE is recyclable and free from harmful substances like phthalates, aligning with sustainable development goals. These characteristics make TPE a preferred choice for applications in automotive, electronics, medical devices, and consumer goods.

-

1.TPE Overmolding for Nylon (PA) Series

Designed for excellent adhesion to PA6, PA66, and PA12, providing superior durabilityand impact resistance.

Model Hardness(Shore A) Tensile Strength Elongation(MPa)(%) Adhesion to PA BD1060/70A 60-70A 4-5 580 Excellent 2.TPE Overmolding for PC/ABS Series

Provides strong adhesion to PC/ABS, ASA, PMMA, offering high flexibility, weather resistance, and soft-touch feel.

Model Hardness(Shore A) Tensile Strength Elongation(MPa)(%) Adhesion to PA BD2060/70 60-70A 5-6 600 Excellent -

-

-

Q

What are the primary benefits of using Thermoplastic Elastomer (TPE) in product manufacturing?

AThermoplastic Elastomer (TPE) combines the flexibility and elasticity of rubber with the ease of processing of plastic. It offers excellent flexibility, allowing it to return to its original shape after repeated deformation, which is crucial for applications requiring constant movement or flexibility. TPE also provides good abrasion resistance and durability, ensuring long-term performance even under harsh conditions. Its wide temperature resistance range makes it suitable for extreme environments, from very cold to very hot conditions. Additionally, TPE is easy to process and can be molded into complex shapes, offering manufacturers significant design freedom and reducing production costs. Being environmentally friendly, TPE is recyclable and free from harmful substances like phthalates, aligning with sustainable development goals. -

Q

How does TPE compare to traditional rubber in terms of environmental impact and recycling?

AUnlike traditional rubber, TPE is fully recyclable and can be reprocessed multiple times without significant loss of properties. This makes it a more sustainable choice, reducing waste and environmental impact. TPE does not contain harmful substances like phthalates, which are often found in traditional rubber products. This makes TPE safer for both the environment and human health. Its ability to be reused contributes to a circular economy, supporting global sustainability initiatives and reducing the carbon footprint associated with manufacturing and disposal.

-